Napier Oryx

As early as 1951 a turbo-gas generator had been envisaged for helicopter propulsion taking the form of the Napier Oryx engine. Working in conjunction with their neighbour at Luton Airport, Hunting Percival (HP), Napiers entered into a new development project in November 1951. A Ministry of Supply (MOS) contract was issued on 8th May 1952 for two Oryx engines installed under the floor of a ‘P74′ prototype helicopter.

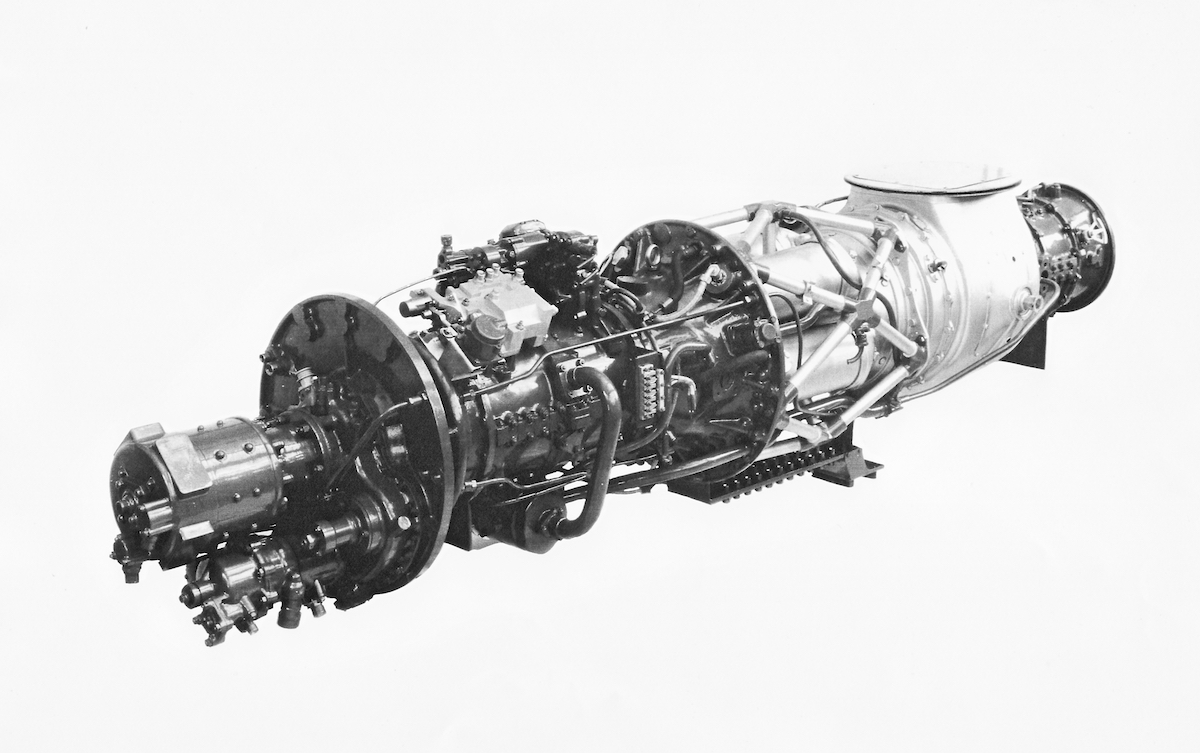

With a twelve stage main compressor of 9.0:1 pressure ratio, running at 21,900 rpm, which supplied five combustion chambers and two stages of turbine to drive it, the Oryx then drove from a common single shaft an additional four stage auxiliary compressor of 1.8:1 pressure ratio. This then provided lower pressure cold air to cool the combined gas collector box and mix (bypass style) with the hot gasses to “Tip Jets’ at the end of the helicopter’s rotors. Such an engine could theoretically pass 29lb of gas/second at 9 psi pressure at 400 degrees Celcius. An engine was been successfully tested at these performance figures and also at a higher 825 ghp for a proposed Percival P105.

This Oryx engine had been fully aerodynamically designed in all its units including non-throttling valve and collector by the Napier Research Station at Liverpool. Unfortunately HP had made some wildly innaccurate assumptions regarding laminar flow within the P74 helicopter’s rotor blades. When tether tested at Luton Airport in May 1956 with two Oryx engines fitted the helicopter achieved precisely NIL vertical lift off!!! Despite a very hasty HP redesgn the whole programme had its funding witdrawn by the MOS since they wanted to centralise its helicopter manufacture elsewhere. So, contrary to (Bill Gunston’s book) D Napier & Son had provided the correct engine power ro no avail.

The concept of tip jet propulsion did not finish here for Napier’s however, the Fairey Rotodyne was flow successfully fitted with two Napier Eland engines and tip jet.