Napier Ramjets

A ramjet is the simplest form of air-breathing engine with air being forced into the engine before fuel is also added and burned with the air. Unlike a gas turbine compressor the greater the air pressure “rammed” into the engine (i.e. the faster it went) the more fuel-efficient it would become. A ramjet comprises an intake (whose design is of vital importance), an expanding diffuser system in which the air-flow is progressively reduced to recover the maximum pressure, a combustion chamber, and a final convergent / divergent propelling nozzle. Its advantage of design is simplicity, lightness, cheapness and ability to burn almost any conventional (and some unconventional) fuel. Ramjets work most efficiently at supersonic speeds around Mach 3 (2,300 mph; 3,700 km/h) and can operate up to Mach 6 (4,600 mph; 7,400 km/h) and generally need to be assisted up to its operational speed by more conventional means.

British ramjet development commenced in 1949 at Bristols and was directed towards the Thor engine series. Napier’s ramjet programme commenced in January 1950 and over the next eight years around 40 Ram Jet Test Vehicles (R.J.T.V.s) were build and mostly fired off into the Irish Sea off Aberporth. This meant much to-ing and fro-ing from Napier’s Flight Development Establishment at Luton to the Welsh Coast with a special trailer containing the test vehicle suitably shrouded in Napier green for the journey.

Napier Luton carried out the design and manufacture of the “aircraft type” parts while Napier Acton was given the task of the design, manufacture and development of the fuel system. Luton had rig facilities to test the systems including a large centrifuge to provide ‘g’ loading. This centrifuge was used for other programmes including testing the overwing fuel tanks fitted to English Electric Lightning!

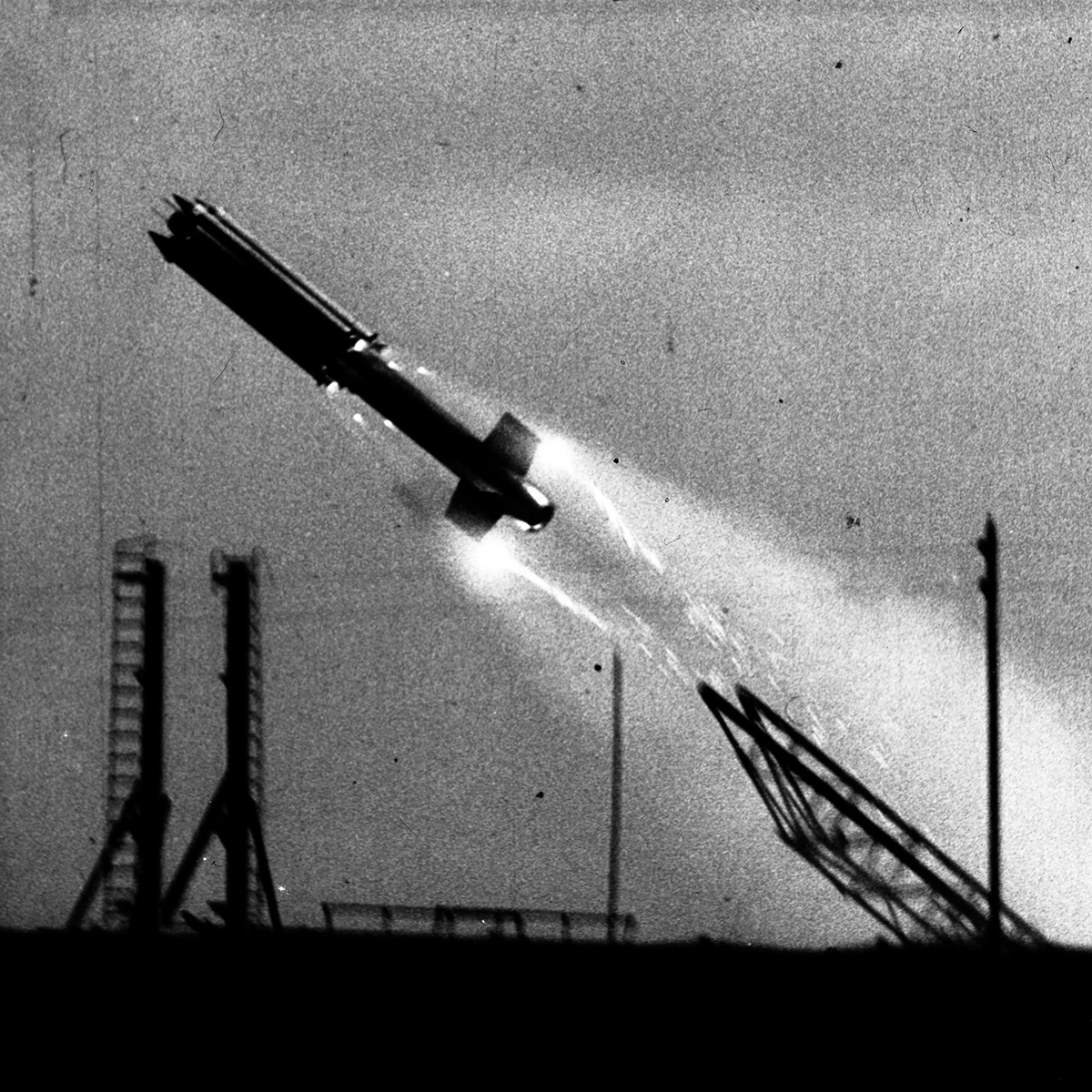

The first ram jet engine designed and manufactured by DNS was an integral part of the rear fuselage and fitted with four stabilising fins. The cylindrical front section contained an internal slab-sided centre body spanning the vehicle’s 16” diameter and housing fuel tanks, metering controls, a telemetry transmitter and Doppler transponder. A series of “cold” aerodynamic test vehicles were used to prove the launching system, operation of the booster rockets, stability, instrumentation, etc. This vehicle was titled R.J.T.V.1 (Ram Jet Test Vehicle 1) and fired in October 1950 at the R.A.E. in Aberporth followed by a further four up to May 1951. Early combustion tests were carried out with constant-flow nitrogen pressurised fuel systems in vehicles launched at an angle of 20 or 30 degrees. Three “kinetheodolite” cameras recorded the vehicle in flight with the trajectory subsequently produced from the film records.

By September 1951 “hot” rounds were being fired and the following month R.J.T.V.8 showed a 1-g acceleration for as long as the fuel lasted. A further six R.J.T.V.’s had been fired by October 1952 at a launch angle of 60 degrees.

R.J.V.T.15 had a more advanced fuel system fitted whose delivery was proportional to the dynamic head measured by pitot and static probes at the vehicle front. The eighteenth ramjet had the booster rockets increased to eight and moved to the rear of the test unit. Finally in November 1954 R.J.T.V.21 was fired with a ram-air turbine driven fuel pump (developed at DNS Acton) drawing fuel from flexible bags. This allowed increased tankage to be provided, so that a break-up charge could be incorporated to prevent danger to shipping near the Aberporth range! Development proceeded upon still more flexible forms of fuel system.

By now Napier R.J.T.V.s had a diameter of 18” and were 20’ long. The intake comprised a ballast ring machined from solid aluminium alloy with the remainder of the fuselage made of wrapped and welded sheet the majority of the rear being stainless steel. Four pairs of solid-propellant rocket motors with an integral stabilising fin and aerofoil at the front surrounded the vehicle. Each pair of boosters were dowelled together so that once their combined drag exceeded their thrust at burn-out all the motors slid to the rear of the R.J.T.V., lifted outwards, and broke away.

Fuel was fed by a turbo-pump fitted with ram intakes above and below the vehicle and exhausting through a pipe on the port side. These Napier vehicles also had eight whip or spoke type aerials, a cooling annulus around the flame tube and a static hole in the propelling nozzle. The fins were wooden skeletons clad with light alloy and bolted to forged light alloy anchors. A temperature resistant paint was applied to both fins and to various parts of the body.

Development work was always marked SECRET until September 1955 when it was publicly revealed that D Napier & Son Ltd were manufacturers of Ramjets for the National Gas Turbine Establishment (N.G.T.E.). By February the following year it was revealed that this Napier product had flown higher than any other British ramjet-powered vehicle and had flown to supersonic Mach numbers with complete satisfaction to the N.G.T.E. and Napier representatives. R.J.T.V. 29 was first shown to the public at Farnborough in 1956.

After 1955 work continued working upon an engine for piloted aircraft or guided missiles. By 1958 a total of 32 RamJet Test Vehicles had been launched. It appears that around 40 were built at Luton as we have definitive information about R.J.T.V. 36 and 37.