Napier Deltic Development

There is a huge following for the Napier Deltic engine especially in railway locomotives. The next few pages reveal a bit more about the many versions of the Deltic engine design that existed. In time our Blog will cover the applications in more detail. If you have interest in a specific Deltic engine application please contact us.

A major problem with the Napier SeaLion and similar engines fitted in the high speed vessels during WW2 was the fact that they were fuelled with petrol. As fuel tanks emptied the air combined with remaining fuel to produce a highly inflammable mixture. This issue was graphically proven to the Allies in Oostende on 14th April 1945 when petrol floating on water in the harbour ignited destroying 12 MTBs, damaging 5 more, as well as killing 73 and injuring a further 84 people.

Unlike the Allies, German fast boats (Schnellboote) were powered by diesel engines which did not encounter these problems. A team of experts was convened under the chairmanship of Sir Roy Fedden to research put forward a proposal for a lightweight diesel engine for marine use. Members included Herbert Sammons, Chief Engineer and later MD of DNS, whose influence was certainly going to help the Company. They produced ‘The Final Report of the M.T.B. Power Unit Committee from October 1943 to March 1944’ (often referred to as The Fedden Report) which recommended a 75 – 80 litre sleeve valved 2-stroke supercharged engine of 2,500 HP. The valve gear was to be of the open-ended sleeve type and the geometric layout to be of the H type using two crankshafts geared to a common drive shaft. This engine bore an uncanny resemblance to a diesel version of the Napier Sabre engine and D Napier & Son were recommended to develop this new engine for the next design of MTB for the Royal Navy. Another engine option was of a triangular opposed piston engine design most likely coming from the Napier design team who had experience of the Napier Culverin which had been cancelled five years earlier. Having current experience of producing the Napier Sabre, the English Electric Company evidently were against the Fedden proposition and proposed to develop the alternative engine. The E.E.Co. offer also stated precisely that D. Napier & Son would undertake the design, development and manufacture of the proposed engine.

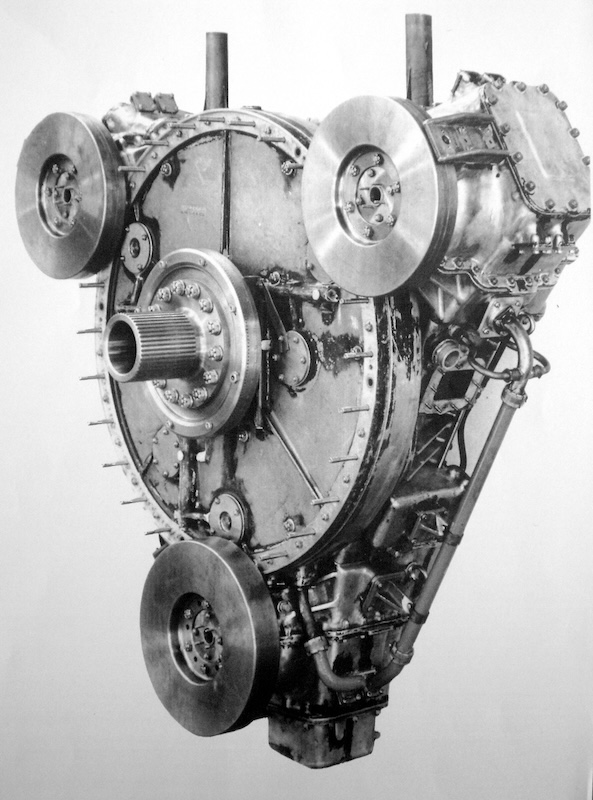

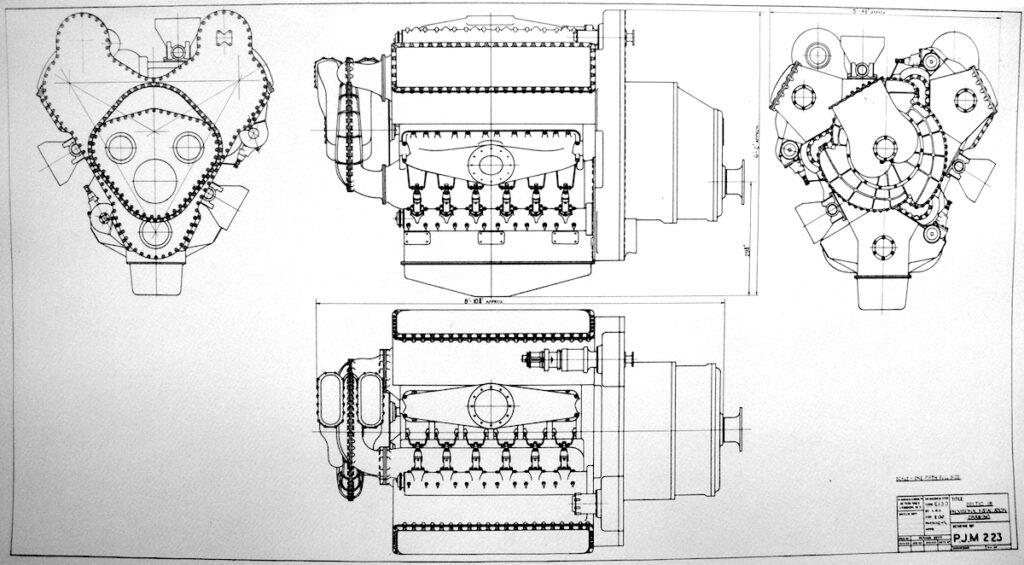

Napier’s unique solution was based on three Napier Culverin aero-engine arranged in a triangular fashion and connected at each corner by a crankshaft. The engine was a two-stroke opposed piston compression ignition (diesel) engine having three or six banks of three cylinders in a triangular arrangement. At each corner of this equilateral triangle is situated a crankshaft, each crank having an exhaust (fork) and inlet (blade) connecting rod from the two adjacent cylinders. The new engine was given the engine design number E130.

In 1946 D. Napier Son received a contract from the Admiralty to design, develop and manufacture :-

(a) Single Cylinder Unit (One leg of the Deltic)

(b) 3 Cylinder Unit (One slice of the Deltic)

(c) 6 x full size 18-Cylinder development engines

George Murray designed a Single Cylinder Unit between October and December 1946 followed by the 3-Cylinder Unit between January and May 1947. The Single Cylinder unit ran successfully from January 1947 onwards.

The 3-Cylinder test unit ran from October 1947 onwards, with a great deal of trouble caused by unbalanced forces and couplings causing excessive vibration. The firing in the Crankshaft degrees was as follows:

” * 40 degree * 40 degrees * 270 degrees * 40 degrees * 40 degrees * 270 degrees, etc ”

This unit was abandoned but it did prove the design of the opposed-piston fork and blade connecting rod assembly in triangular arrangement. In the meantime, the Scavenger Blower was designed, manufactured and rig tested from November 1947 onwards. The main engine design also proceeded and was completed by the end of 1948.

Around this time a compounded 18-cylinder version of the engine was also considered and Single Cylinder Tests were carried out.

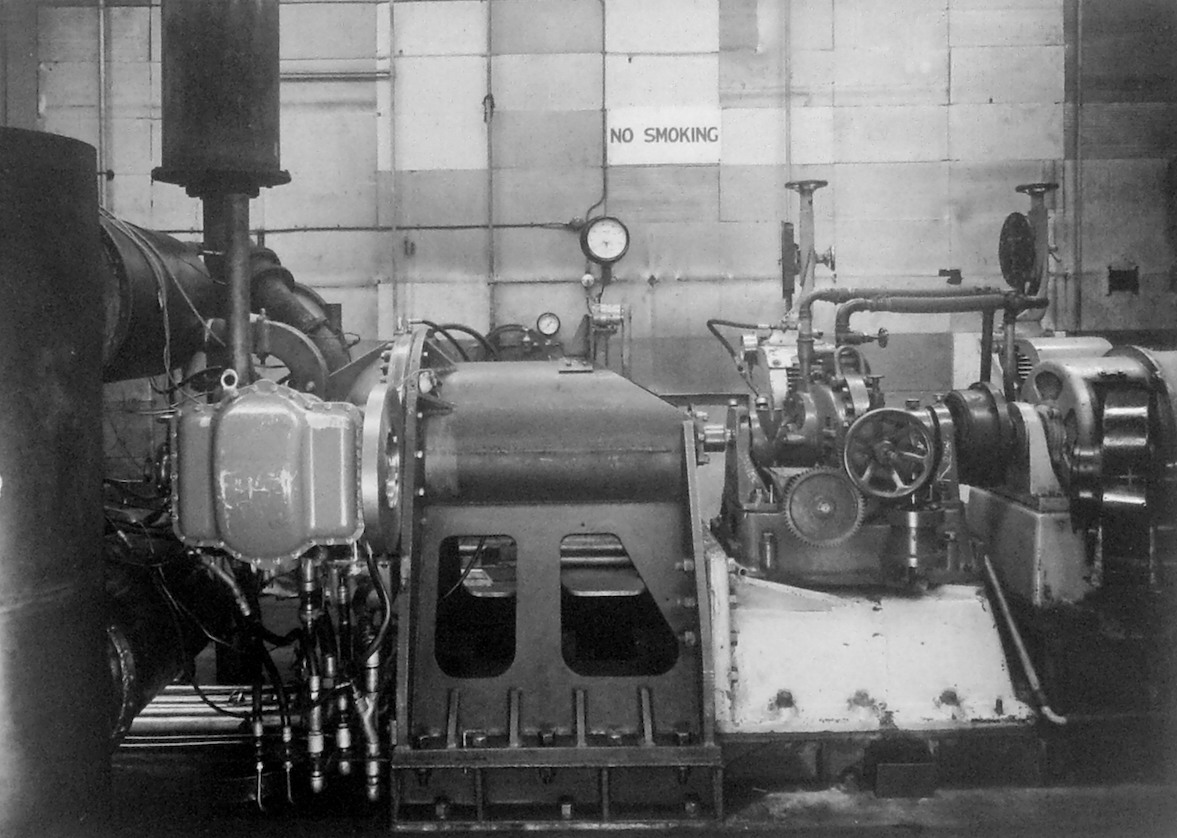

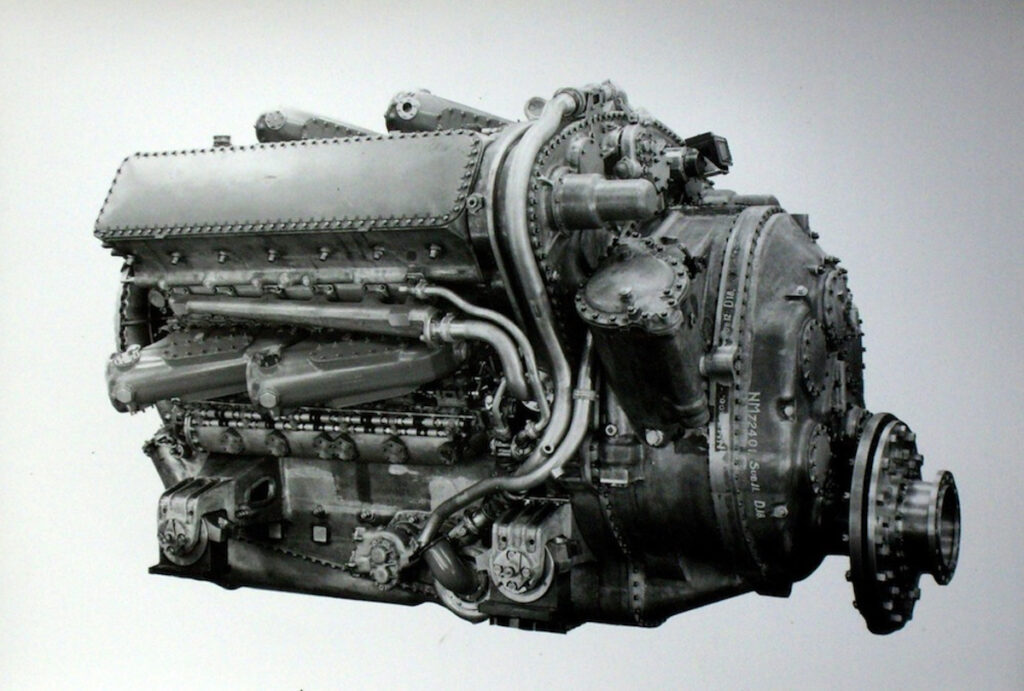

The first engine, designated D18/1, was designed to produce 2,500 BHP at 2,000 RPM and became the prototype Deltic 18-11B intended for installation in new Royal Navy Dark Class motor torpedo boats for which the engines were designed. It first ran on the test bed in April 1950.

A derated 1,500 BHP engine was created from the final development engine (D18/6) for use in the Ton Class minesweeper along with a 9-Cylinder Pulse Generator Set (production engine Serial No. 10). Two of the six development engines (D18/4 and 5) were installed in an ex-German E-boat (RN Pennant P5212) at HMS Hornet and ran extensive successful sea trials from late 1951 onwards. P5212 was the first ‘Deltic Prototype’ and the engines proved themselves fit for the purpose they were designed for.

Recent posts

PL4 – A Bigger and Faster Boat for Shell

This is an edited article originally from ‘This is Napier’ No.5 1959 During 1957 the Compania Shell de Venezuela took delivery of three high-speed passenger launches for service on Lake Maracaibo between land bases and [...]