Napier Deltic Series 1 engines

The first production engines weren’t for the Royal Navy as one might expect. Instead George Nelson, Chairman of the English Electric Group, negotiated with the Admiralty and persuaded them to release the first three for use in a project being privately financed by EE. The engines were designed to be fitted in ‘DELTIC’ a prototype railway locomotive that was destined to make the engines famous the world over.

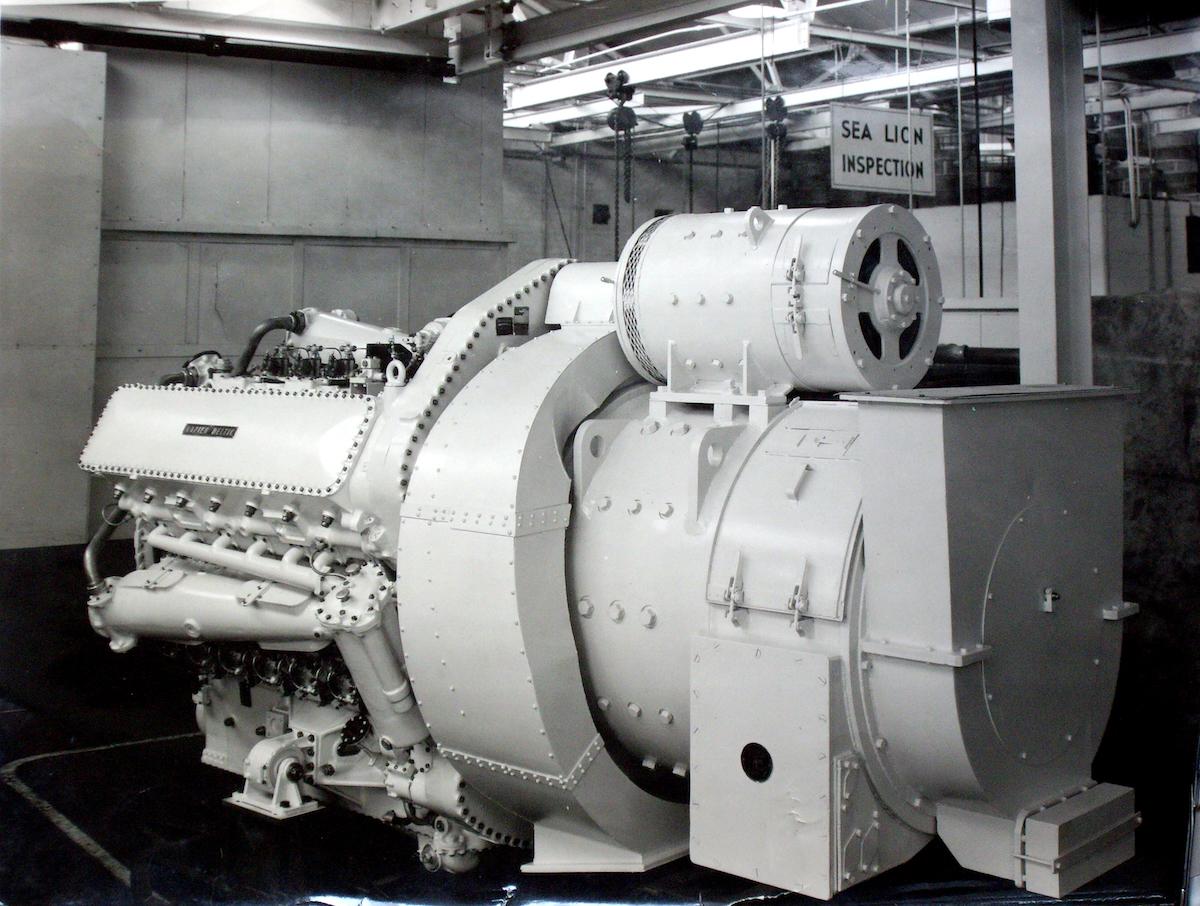

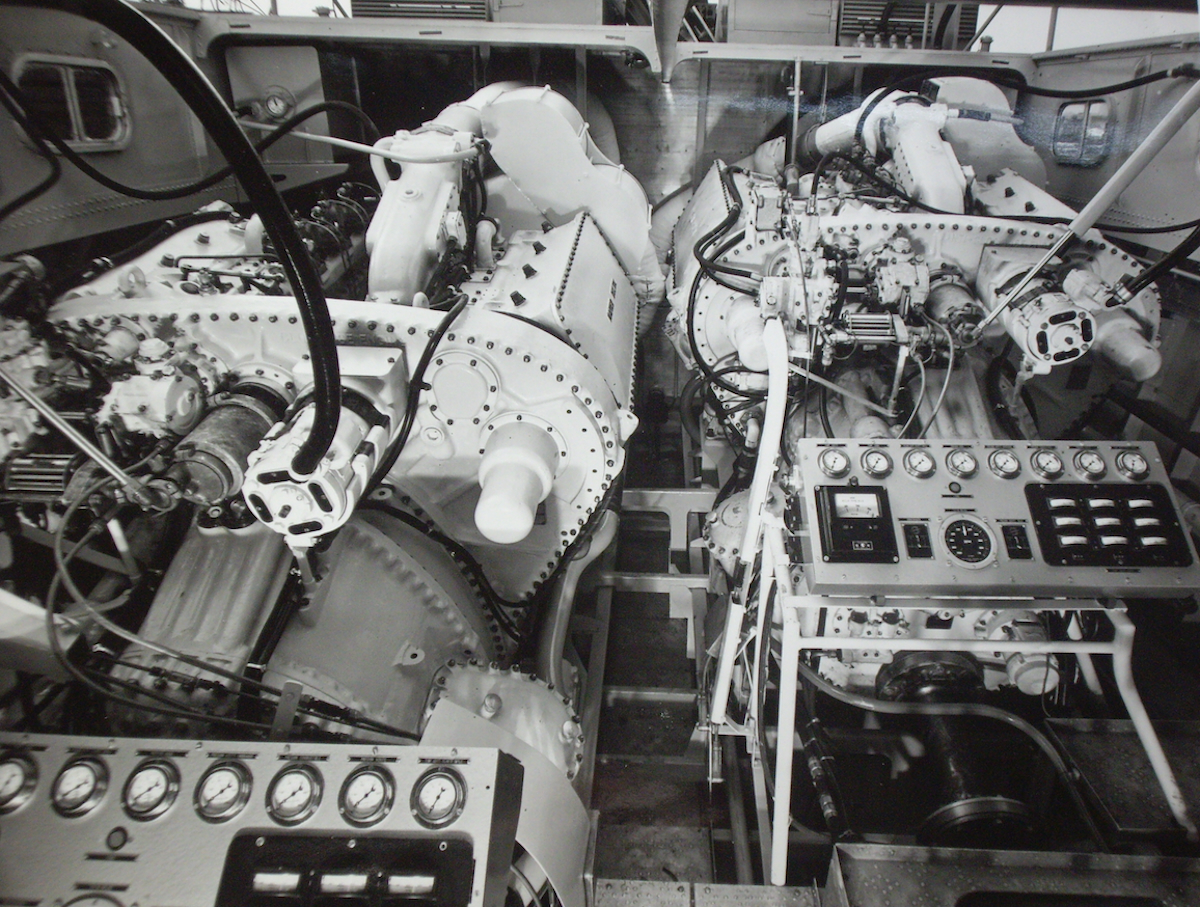

E130 Deltic 18-12A

An 18 Cylinder ‘Deltic’ engine of similar design to 18-7A engine, required for Rail Traction purposes, without an ahead and astern gearbox, and incorporating special phasing gear casing for flange-mounted generator. 1,650bhp at 1,500 crank shaft output rpm. Initial locomotive application only.

After that next 100 or so engines produced were all for the Royal Navy and comprised three versions.

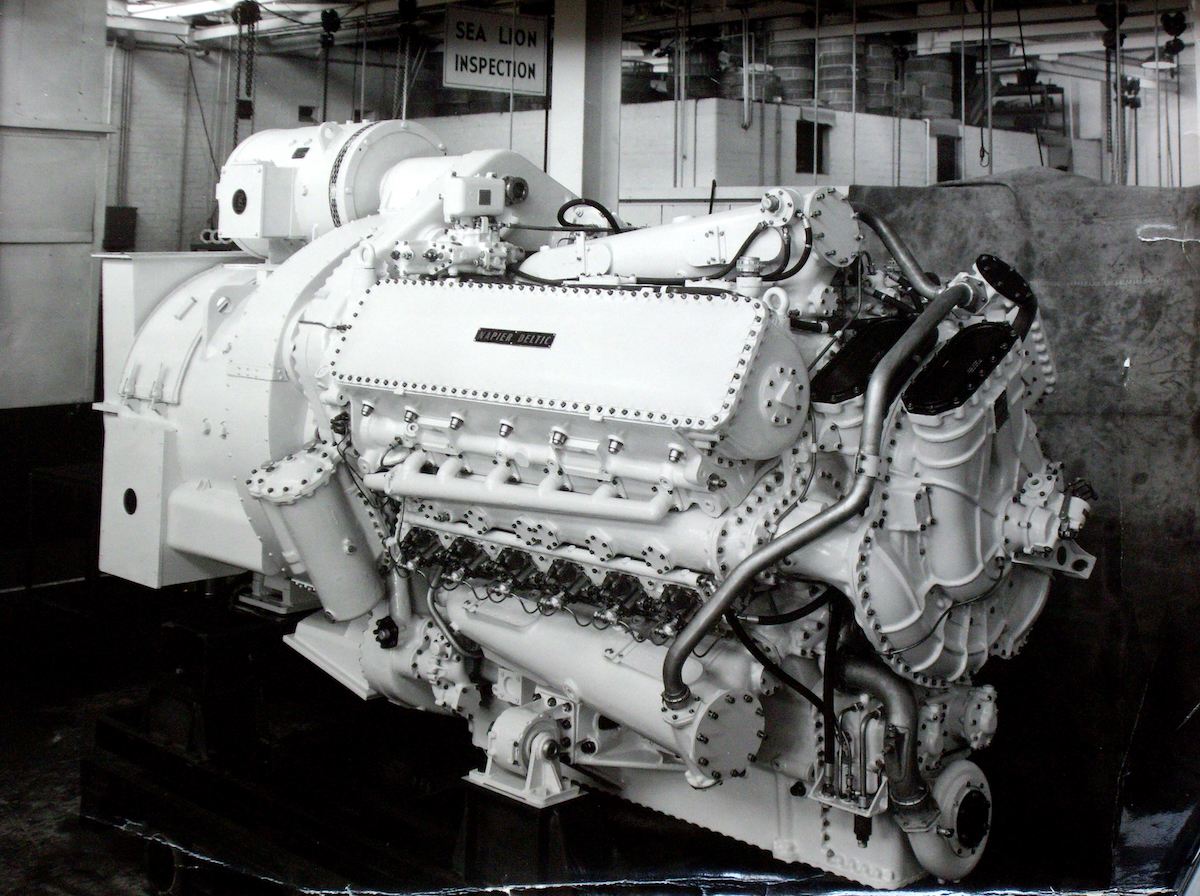

E130 Deltic 18-11B

An 18 Cylinder production ‘Deltic’ engine incorporating a twin plate clutch with increased scavenge blower drive ratio (5.72:1) to cater for 1lb/sq.in exhaust back pressure 2,500 bhp@ 2,000 crpm (950rpm output shaft speed). There were two types of gearbox – clockwise and anticlockwise – and were fitted in pairs as propulsion engines for RN Dark Class MTBs. They were also supplied to Burma, Finland, Germany, Israel, Japan, Norway and Yugoslavia for a variety of projects including the prototype for Norways Tjeld class MTB named “NASTY”.

111 engines manufactured.

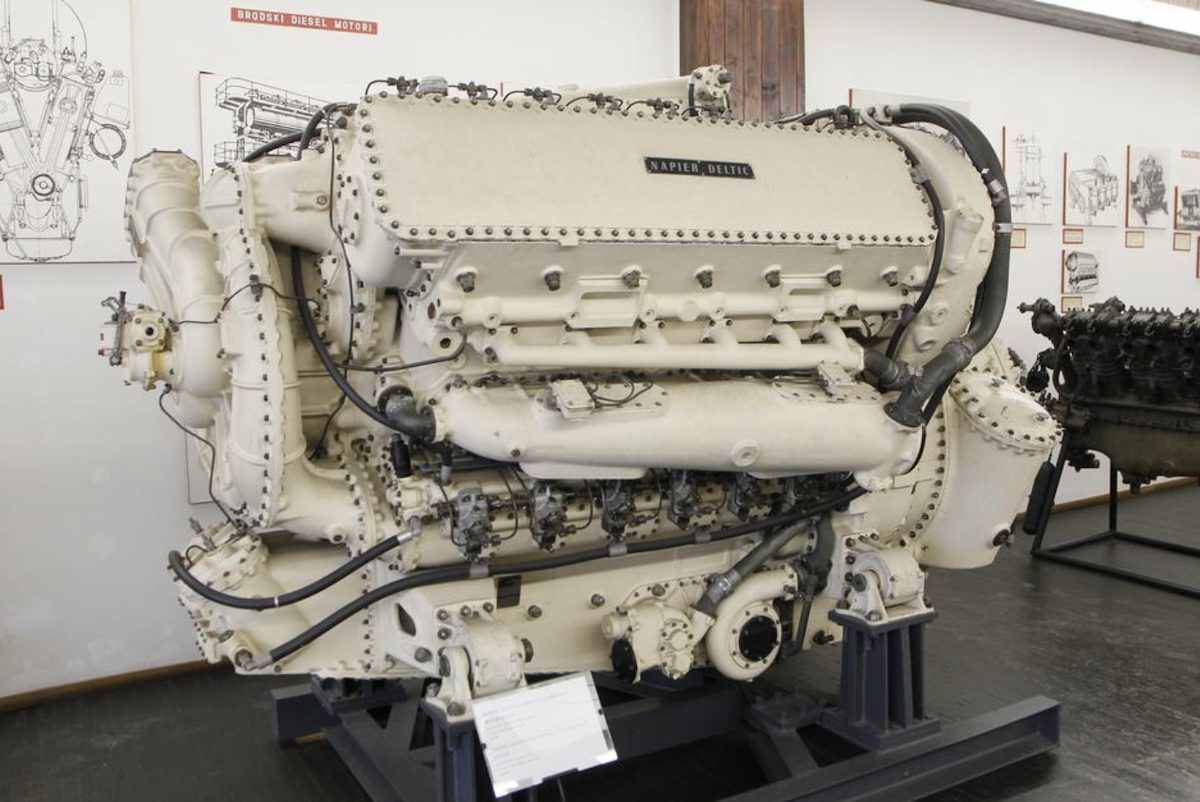

E130 Deltic 18-7A

A lower rated 18 Cylinder production ‘Deltic’ engine, similar to type number 18-11B for Minesweeper propulsion, 1,500 bhp @ 1,400 crpm (400rpm output shaft speed). Pairs of main propulsion engine for Ton Class Minesweepers and like the Deltic 18-11B had clockwise and anticlockwise gearboxes. The Ton Class minesweepers were also supplied with Deltics to Argentina, Australia and South Africa.

232 engines were manufactured of which 44 were converted from 18-11B engines after the Dark Class engine order was reduced.

E159 Deltic 9-5A

A 9 Cylinder ‘Deltic’ engine required for Pulse generating of the same configuration as the E130 series, with phasing gear of similar design to 18-12A engine for flange mounted generator, 875bhp @ 1400 crank and output rpm. Fitted in many Ton Class Minesweepers and also supplied to Australia and South Africa. One of these engines is reputed to have been reconditioned and sold to J. Stone & Co. for testing their Mekydro transmissions for the British Railways Hymek locomotives.

85 manufactured in total.

Further Series 1 engine types manufactured included:

E165 Deltic 9-5B

A 9 Cylinder ‘Deltic’ propulsion engine and similar to 9-5A, but with phasing gearbox and ahead and astern gearbox as 18-11B, 825bhp @ 1,500 crmp and 710 output shaft rpm. These engines were installed in three small high passenger launch manufactured by Thornycroft for use by Shell to ferry employees around the various drilling platforms on Lake Maracaibo in Venezuela.

9 engines manufactured.

E130 Deltic 18-11B(U) / 18-11B(L)

Three 18-11B engines were manufactured and registered with Lloyds of London for use in RCMP Fort Steele by the Royal Canadian Mounted Police to patrol the Great Lakes.

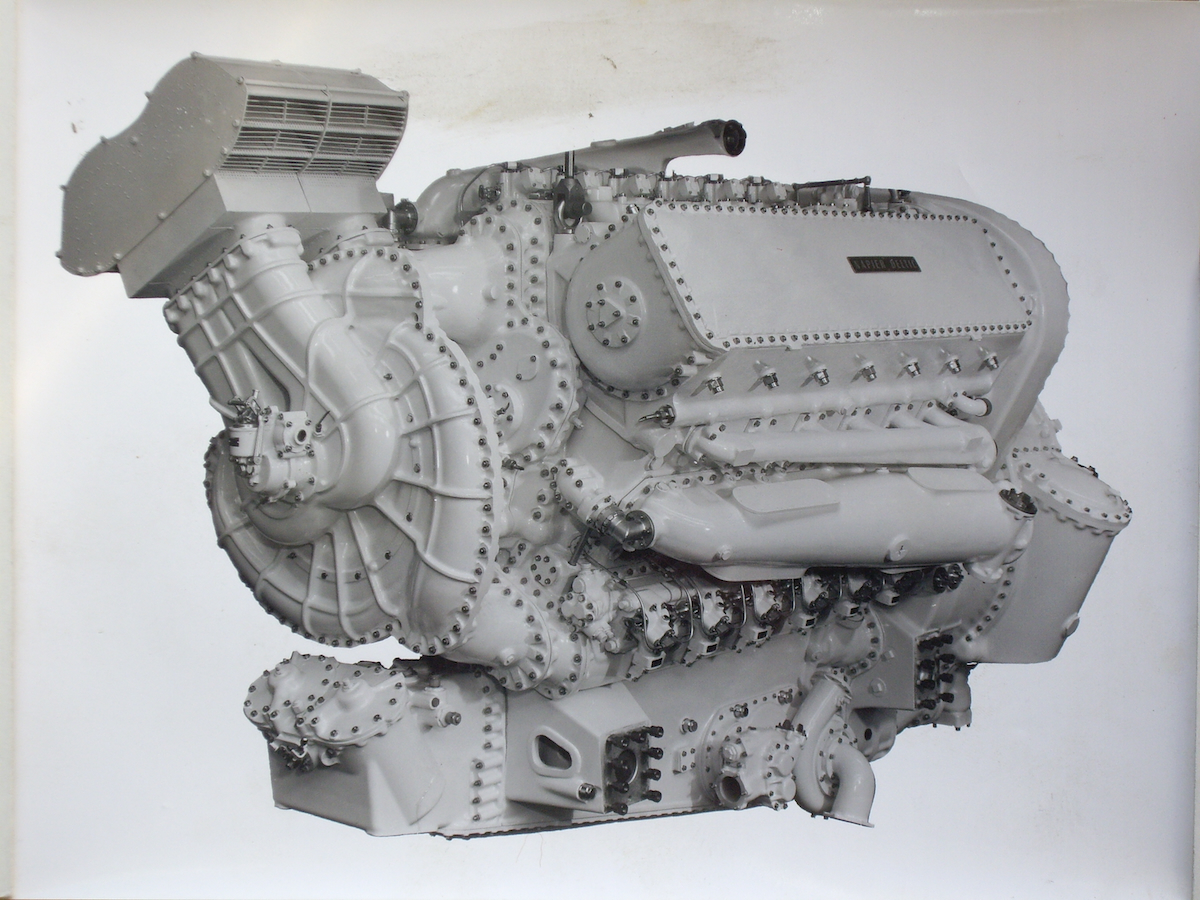

E183 Deltic 18-25B

An 18 Cylinder industrial engine for a 50 cycle, pedestal bearing alternator , similar to the 18-25 engine, with high output shaft and end cover to suit. 1,725bhp @ 1,500crpm and output shaft rpm.

A single engine was supplied to a sister company in the EE Group, Marconi Wireless in Chelmsford. As will be seen, this engine was converted to a Series 2 design in 1958.

The original production Deltic engines were built to Ministry specifications and to a very high and exacting quality. For example every casting was machined for interchangeability whether required for that particular engine design or not. If a machined area was not required a plug with associated studs, tab washers and nuts were fitted. In common with standard Napier aero engine practice every component was also numbered for easy identification. The Deltic parts had the prefix “NM” (Napier Marine) applied. Whilst all this was an excellent idea it increased manufacturing costs making them expensive especially if they were to be sold in the commercial market and this lead to the development of the Series 2 design.

Recent Posts

PL4 – A Bigger and Faster Boat for Shell

This is an edited article originally from ‘This is Napier’ No.5 1959 During 1957 the Compania Shell de Venezuela took delivery of three high-speed passenger launches for service on Lake Maracaibo between land bases and [...]