As already mentioned, the original Series 1 Deltic engines designed for the Admiralty were expensive to produce. D Napier & Son had an agreement with the Admiralty that the Deltic design could be developed and sold to other customers. Very soon it was recognised that if the Company was to have any commercial sales then the engines would have to be “of cheapened construction”. The Deltic was designed for use in different scenarios and had already been fitted with a forward / reverse gearbox and flange mounted generator. As far as possible components were standardised meaning that, for example, a machined hole might not actually be used in that particular engine. This meant that an additional plug or cap would have to be manufactured and fitted at extra cost with no real benefit.

In 1954 a Deltic Design Study Group was formed to find methods to simplify engine manufacture whilst also improving engine functional operation. A new Deltic standard (DS102) was created which not only made it cheaper to produce but also introduced design improvements. Externally the change was immediately apparent by the considerable reduction in the number of studs attaching the crankcase cover to the engine. More importantly the cylinder block had been redesigned incorporating an improved engine coolant circuit which equalised flow rates to individual cylinders. The redesign also saw the manufacturing cost of raw casting reduced by 25%. Taking this and reductions in machining and other manufacturing costs into account, the net result was that the cost of a Deltic engine was almost halved from £30,000 to £16,000. In today’s terms this is a reduction of £310,000 from around £660,000 to £350,000!

The Series 2 Deltics did see commercial sales, 125 engines being sold for a diverse range of applications which can be split into two groups – land and sea.

Land

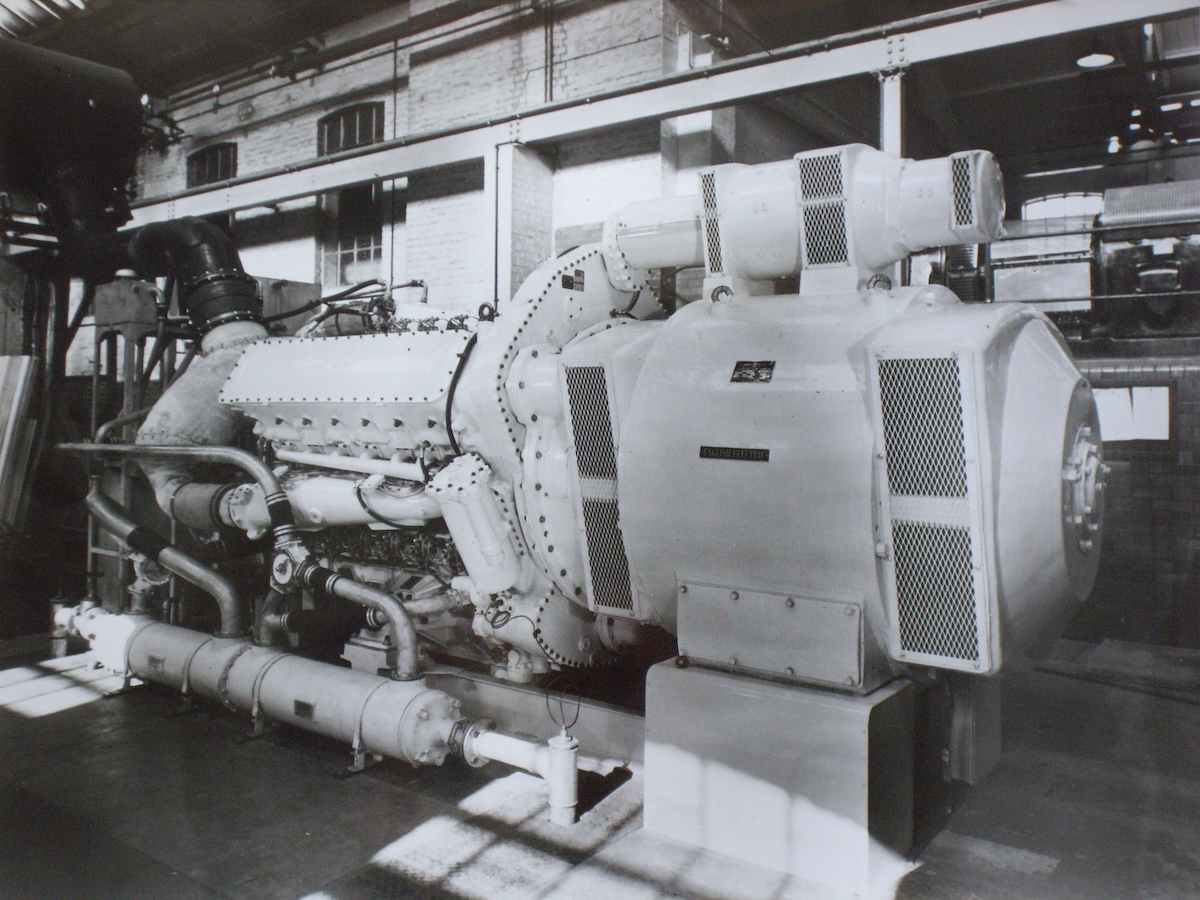

Since the Series 2 Deltic engines were intended for commercial use it was prudent to supply an early engine to another company in the English Electric Group for assessment. During an overhaul in January 1958 Series 1 engine (S/No. 174) was converted to the new Series 2 standard as a 18-25C and returned to Marconi in Chelmsford.

E183 Deltic 18-25C

An 18 Cylinder industrial engine for a 50 cycle, pedestal bearing alternator, similar to the 18-25 engine except for the output shaft arrangement and the exciter drive with a gearbox giving 1:1 ratio. 1,725bhp @1,500crpm and output shaft rpm.

A comment in the Napier Company minute book reported that “This installation has performed most satisfactorily and is available for demonstration to interested persons”. This led to sales of similar engines to the Diplomatic Wireless Service who purchased six engines to this standard. Four of these engines were originally turbocharged (T18-27B 2,200bhp @ 1,600crpm) engines but converted to blown engines due to the strain put on the turbocharger gears by rapid changes in engine load.

The most common land based application for Deltics was in railway locomotives. There were two series 2 engine designs for rail traction though many other designs and applications were considered!

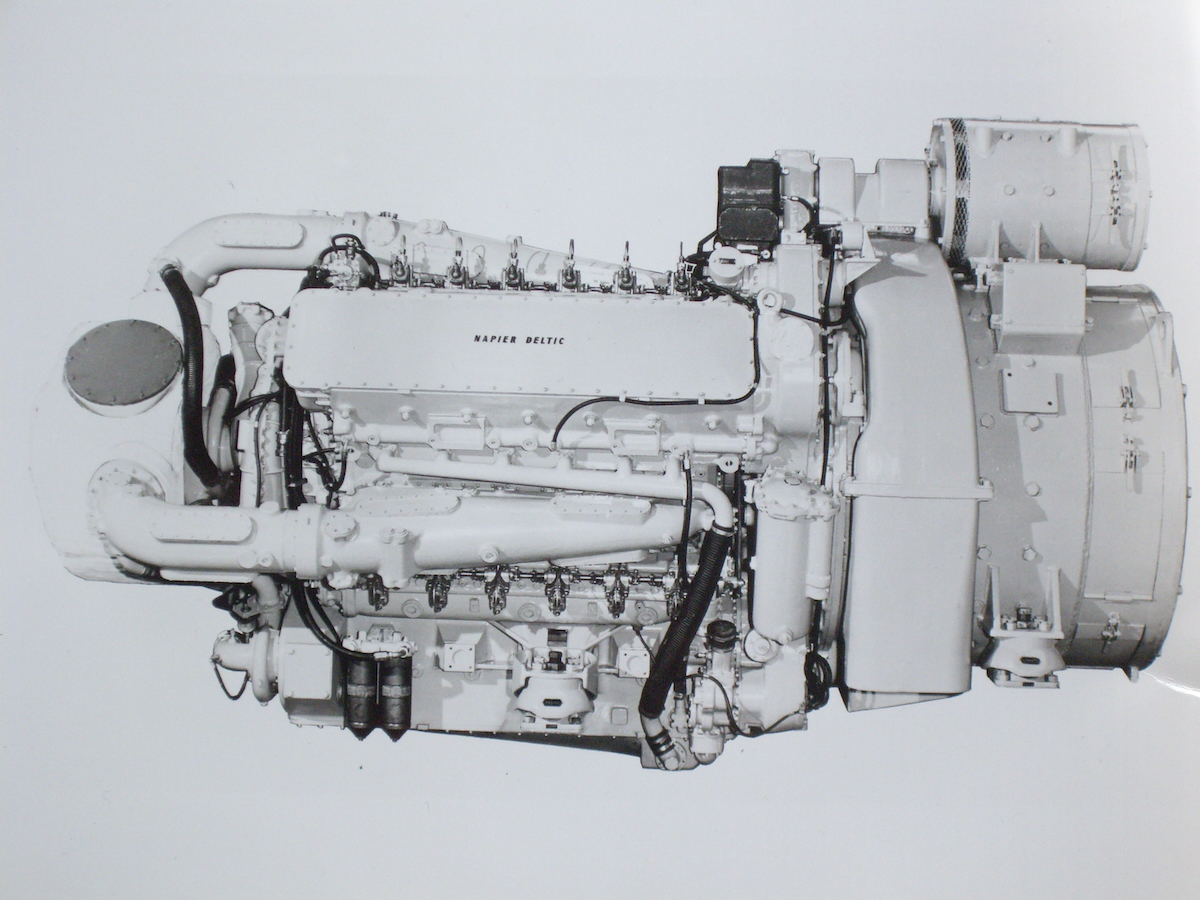

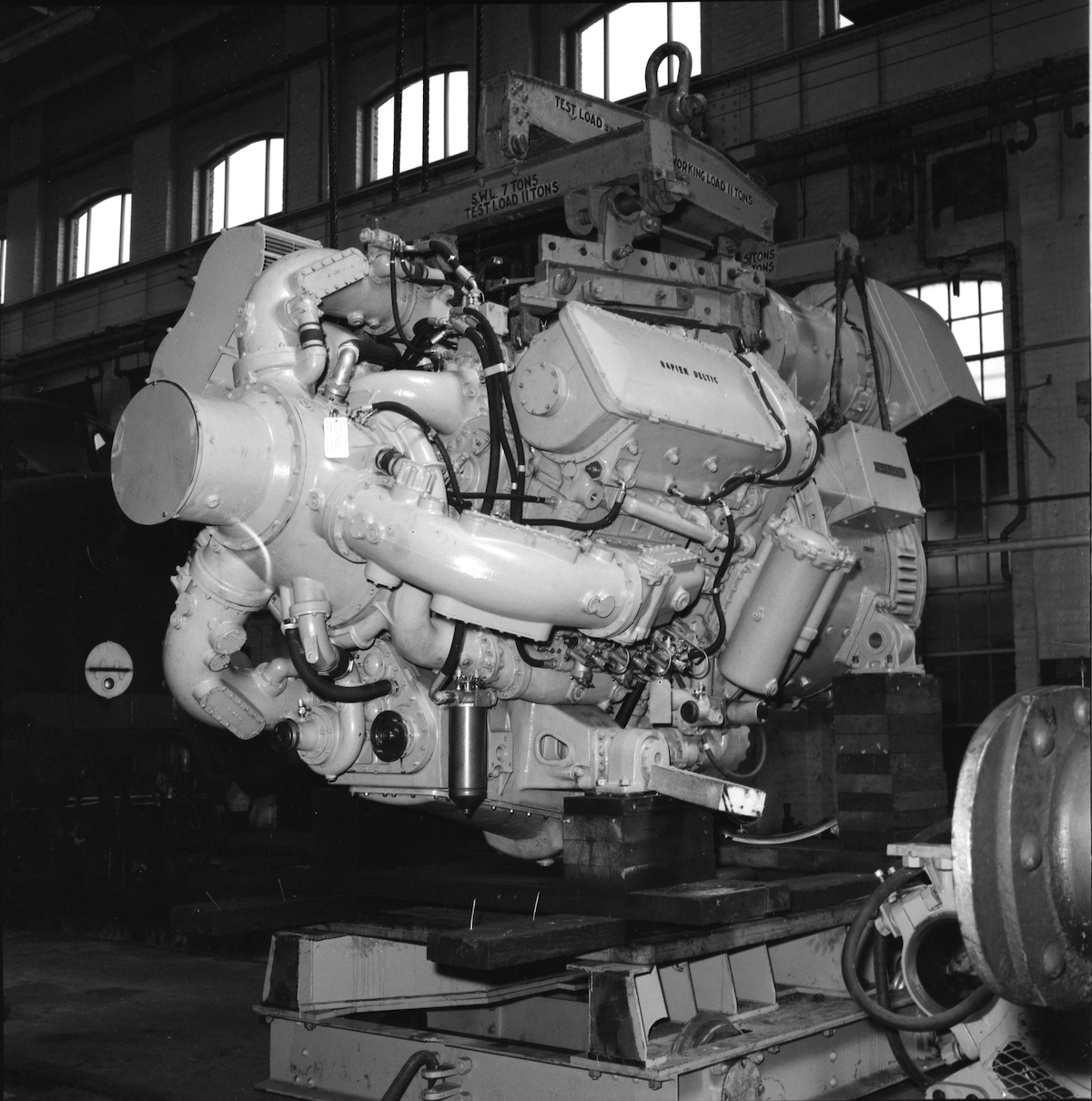

E169 Deltic 18-25

An 18 Cylinder engine similar to 18-12A (engines for Deltic Prototype locomotive) for Rail Traction purposes incorporating special phasing gear casing for flange-mounted generator and to DS102 standard. 1,725bhp (later reduced to 1,650 bhp) @1,500 crank and output shaft rpm.

58 engines produced however two were to Series 3 standards.

E172 Deltic T9-29

A 9 Cylinder engine similar to 9-26 for Rail Traction, but with a turbo-blower geared to the crankshaft, incorporating DS102 standard. 1,100bhp crank rpm 1,600 – output shaft rpm 1,600.

Fifteen of these engines were manufactured for the Class 23 “Baby Deltics”. They were also the first turbocharged Deltic engines to enter service.

Sea

The first Series 2 engines were supplied to Vospers for PL4, a larger and faster passenger launch for Shell on Lake Maracaibo.

E169 Deltic 18-25K(L)

An 18 Cylinder ‘Deltic’ Marine engine similar to 18-25K but to Lloyds specification, 1,650bhp @ 1,500 crank and output shaft rpm.

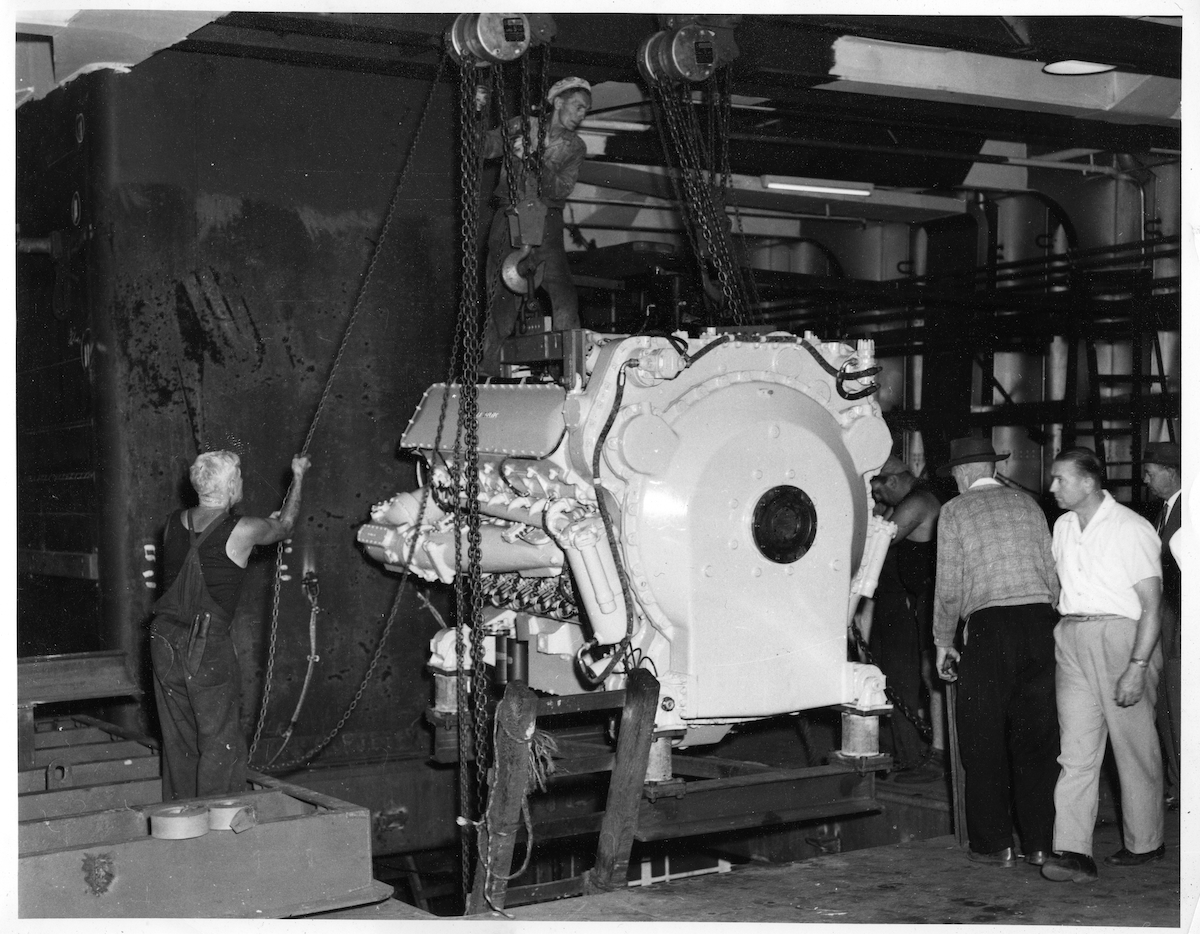

Nine of these engines were produced with a further two being converted from T18-37K turbocharged engines. The history of these engines is complicated and needs a separate article but were fitted in three vessels: Shell’s PL4, the Sheik of Qatar’s luxury yacht “Naief”, and Bahama King an ore carrier. There were high hopes for the Deltic trial in Bahama King since the high power to weight ratio and compact size of the engine would reduce the engine room size and increase hold space. Additionally the Deltic’s repair by replacement ability would reduce costly down time while the vessel was in dock being repaired. However the installation of Deltics in “Banana King” as it became known was not a success due mainly to the cargo acting as a grinding paste on engine components!

E243 Deltic T18-27C(L)

An 18 Cylinder ‘Deltic’ turbo-blown engine to Lloyds specification, Crank rpm 2,100 bhp @ 1,600 rpm but with a high output shaft and end cover. Rather than having a gearbox or generator attached these engines featured a simple output from the centre of the phasing case. This drove an external hydraulic coupling into an epicyclic gearbox which in turn drove a Stone-Kamena reversible controllable pitch propellor. The whole design meant that Bass Trader had a much more compact engine room design than any comparable vessel of the time.

Five of these engines were produced and fitted in Bass Trader the first Roll-On Roll-Off ferry in the souther hemisphere and was the first merchant vessel specifically designed to operate with Deltic engines. Bass Trader entered service in April 1961 and plied its trade across the Bass Strait between Melbourne and several small ports in Tasmania until 1974.

Provision was made to carry a spare engine was made on the vehicle deck of Bass Trader which subsequently made maritime history when it became the first ship to change an engine at sea. The Napier concept of repair by replacement had been proved.

E239 Deltic T18-37K

An 18 Cylinder ‘Deltic’ engine for MTB duties, with a turbo-blower geared to the crankshaft. 3,100 bhp @ 2,100 crpm. Unlike the Deltic 18-11B this engine had a new gearbox developed which could be changed from clockwise to anti-clockwise rotation by swapping two high pressure pipes over. One engine from Bahama King was used as a development engine for the 3,100 bhp T18-37K.

161 engines were constructed of which 32 were Series 2 engines. The Royal Norwegian Navy had 28 of these and the remaining four were sold to Germany who had purchased two vessels from Norway named Hugin and Munin.

With the engines now being turbo-charged and producing increasingly higher power output from the same basic triangle a further redesign was required and the Series 3 Deltic was created.

Recent Posts

PL4 – A Bigger and Faster Boat for Shell

This is an edited article originally from ‘This is Napier’ No.5 1959 During 1957 the Compania Shell de Venezuela took delivery of three high-speed passenger launches for service on Lake Maracaibo between land bases and [...]