Sabre Engines with Bulk Injection carburettors

The later Series IV Sabre engine was fitted with bulk injection carburettors. It had a single entry supercharger with strengthened supercharger and reduction gear drives to withstand the higher gross powers which result from the use of higher boost pressures coupled with higher ratio supercharger drives. In addition these engines incorporated sundry technical improvements including boost and r.p.m. corrected ignition, and an improved supercharger clutch.

At first the Series IV engine utilised S.U. twin-choke suction carburettor but this was soon changed to a Hobson-R.A.E. injection carburettor and intensive development of this unit followed.

The Series IV engine was superseded by the Series V (E107C) engine in 1943. Both series of engines commenced life with fully balanced crankshafts and developed 2,180 BHP at 8,500 feet (at 4,000 CRPM +9 psi boost). As a result of torsiograph tests it was decided to remove the balance weights from the crankshafts and reduce the maximum RPM slightly owing to the presence of a certain amount of torsional vibration at the top of the speed range.

Gradually the power output of the Sabre V was stepped up until in November 1944 a development type test was passed at a combat power rating of 2,600 BHP. Technical improvements to the engine were continually being added and ultimately the production engine, the Series VA, passed an official type test at the N.S.81.S.M. Rating in June 1945.

The Sabre VA incorporated the following:-

- Single lever control

- Improved oil sump

- Improved auxiliary drive casing

- Increased coolant flow through cylinder blocks

- Strengthened reduction gear

- Single piece sleeve drive idler gears.

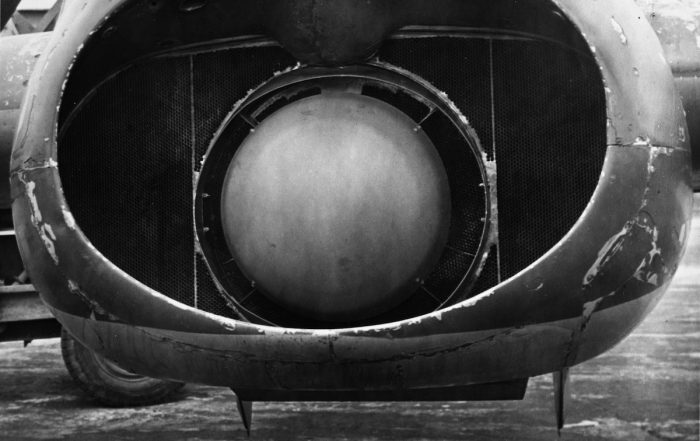

Concurrently with the development of the Sabre V, a modified version of the same engine, but incorporating a gear driven cooling fan in the nose for use with annular radiators, was developed and designated the Series VI engine. A small number if engines have been built for flight trials in “Tempest” and “Warwick” aircraft at Napier’s Flight Development Establishment at Luton Airport.

In the summer of 1945 tests were commenced using water/methanol injection to increase the power rating with standard fuel. These tests were entirely successful and the Series VII (E121) design evolved. This strengthened and improved engine, incorporated many refinements including an improved axial-flow air inlet bend. It completed a type test later in the year at a take-off 3,000 BHP and a combat rating if 3,055 BHP at 2,250 feet altitude.

The Hawker Fury was the next development after the Hawker Typhoon and Tempest. Hawker Fury Prototype LA610 was fitted with a Napier Sabre VII to become the fastest piston-engined Hawker aircraft after reaching a speed of around 485 mph (780 km/h).

The Sabre VIII (E122) Series engine of higher boost with 2 stage 3 speed Supercharger, contra rotating propellers and fan drive engine capable of 3,350 BHP was proposed but never built.

Testimony was given to the development in the Sabre design by the power/weight ratio figures. The series I had a ratio of 1.55 lbs. per BHP. This was improved to 0.922 lbs. per BHP for the Series IIC and, with the advent of the Series VII the ratio was further reduced to only 0.831 lbs. per BHP. The maximum permissible boost figures also, over the last five years, by 10.1⁄4 lbs. from the original value of 7 psi to 17.1⁄4 psi. The rise in power output and performance is the more remarkable when it is remembered that the development covered a period of only 10 years, 5 of which the engines were in full production in wartime conditions.

Recent posts

The Napier Sabre Chin Radiator

When the Hawker Typhoon aircraft was being developed Sidney Camm and his team had to find a way to efficiently cool the Napier Sabre engine. Overheating had plagued the Sabre throughout the engine's development [...]

Napier and Martin Baker

In 1934 the Martin-Baker Company designed a small cheap two-seater mono wing aircraft which exploited a simple highly ingenious method of construction. It used round section thin gauge steel tubing throughout the structure and [...]

Napier Sabre Annular Radiator

Both the Hawker Tempest and Typhoon aircraft featured an instantly identifiable and large 'chin' radiator. This was because the aircraft required sufficient airflow to cool the large and powerful Napier Sabre engine. However the [...]

The Napier Sabre Momentum Air Filter

After the WW II Normandy landings on the 6th June 1944, temporary landing strips were constructed close to the beaches from which Hawker Typhoon aircraft could operate. Flying from these [...]